Performance overview

Everything food businesses need

Function modules and apps form the basis for our flexible and customizable software. This principle also enables us to connect existing enterprise software in an intelligent network to form a meaningful whole. In addition to investment security, the multiple award-winning database also guarantees maximum processing speed and allows evaluations directly on the operational data.

The overall solution from agmadata covers the entire core business. The system is adapted to the operational processes, whereby individual modules can be added at any time or implemented with little effort. In addition, universal interfaces are available to connect further systems as required. For electronic communication with customers, suppliers, business partners and public authorities. For transferring invoice data to an accounting system. For archiving documents in a DMS. For communication with warehouse control and automation technology. And for many other tasks.

The function blocks of iFood

- Overview

- Basic data

- Procurement

- Stock and inventory

- Sales

- Production

- Calculation

- Quality management

- Meat cutting

- Store

- Livestock

- Extras

Overview

Basic data

Article master

- One article master for all articles (raw materials, semi-finished products, finished products)

- Alternative article and match code

- Assignment of any number of conversion units

- Image, graphic and document can be stored for each article

- Classification via free classification criteria (characteristics)

Address master

- One address master for all company divisions

- Attachment of different delivery and invoice addresses

- Representative assignment

- n‑Contact

- Hierarchies for mapping the entire trade

- Assignment of supplier / customer information

Price list management

- Central price maintenance for all divisions

- Standard / special / promotion / basic price lists

- Procurement

- Stock assessment/inventory

- Meat cutting, recipe

- Calculation/contribution margin

- Sales, Store

Discount / Bonus Management

- Central maintenance of discount and bonus agreements for all company divisions

- Customer/supplier discounts fixed, staggered, period-dependent

- Bonus agreements percentage, lump sum, graduated and incremental bonus

Assortment management

- Assortment for customers/suppliers

- Assortment-dependent data acquisition

- Assortment-dependent purchasing

- Assortment-dependent price list printing

Text management

- Central text management for all company divisions

- Ingredient texts

- Manufacturing instructions

- Labeling texts

- Text modules for all document types order, delivery bill, invoice etc.

- Fixed and variable texts per customer/article or supplier/article

Procurement

Inquiries

- Enter supplier requests

- Compare price requests

Ordering

- Single or weekly order

- Receipt printing in different languages

- Order history

- Display of the last 10 orders

- Supply information (who supplies what at what price)

- Assortment check

- Display supplier conditions (bonus, discount, cash discount, promotional prices)

- Supplier price comparison

- Purchase order proposals (price comparison under consideration of conditions)

- Scale price function

- Price maintenance in foreign currency

- Approval release

- Minimum acceptance test

- Order substitution function

- Daily/weekly/monthly overview

- Order overview / disposition per disposition type (meat, spices…)

Contracts

- Contracts/agreements

- Contract reservation via purchase order, debit via goods receipt

- Contract evaluations

Calculation

- Online average price calculation as a basis for

- Commercial transactions

- Dismantling calculation

- Recipe calculation

Goods receipt

- Order overview with takeover

- Manual acquisition/weighing/scanning

- Batch proposal

- Enter supplier batch

- Quality queries pH value, temperature

- Labeling*

- Direct stock posting

- Empties management

- EDI RECADV*

- Transfer to the audit

Audit

- Transfer of goods receipts to the invoice verification process

- Payment blocks

- Charge-out function

- Debit notes

- Transfer to financial accounting (standard DATEV)

- Transfer to archiving systems*

- Handover to statistics

*optional

Evaluations

- Order statistics, goods receipt statistics

- Evaluations for suppliers / supplier groups according to article no., article/merchandise groups

- Predefined evaluations

- Supplier Management Info (KMIS)

- Interface to EXCEL/ACCESS

Stock and inventory

Basic data

- Bearing no., bearing area, bearing type, bearing type

- Inventory management in parallel in 2 units pieces/kg, cartons/kg, pallets/kg etc.

- Storage bin management

- Check for minimum/maximum stock

- Setting evaluation procedure

Shelf and bin management

- freely definable warehouses, storage locations and bays

- Storage strategies (ABC)

- Rack/sliding/import/block warehouse

- Locking function

- EAN and NVE Labeling*

- Driving and retrieval orders for forklift and/or MDE devices

- Stock removal planning

- Stock money statement

Stock transfer / booking functions

- Stock transfer functions (weighing, scanning, manual input)

- Stock transfer order, freight order, exemption order

- Charge-off functions

Material debit

- Automatic material debiting via cut lists (retrograde debiting)

- Third-party storage/warehouse money settlement

- Customer-related or sales order-related inventory management (advance production)

- Mixed pallet management

- Pallet/carton and single piece picking

Control / Traceability

- Key date movement logs

- Transaction logs for stock transfer, receipt, issue, cancellation, reservation, inventory, deletion

- Movement log per date, time, workplace, operator

- Batch/pallet/crate and part tracking from goods receipt through all process stages to shipping

Inventory /Valuation

- Weekly, monthly, annual inventories

- Inventory for article/item/goods groups

- Closing date inventory

- Manual or automatic stock difference clearing

- Different valuation methods Purchase price, valuation price Cost price (purchase price + cost)

- Inventory evaluation TARGET/ACTUAL

*optional

Evaluations

- Disposition lists, minimum stock report

- Key date evaluation

- Difference lists (shrinkage per process)

- Article stocks according to storage, storage location and blocked stocks according to articles and main, goods, article groups

- Storage date, best before date, ripening date

- Minimum stock determination/notification

Batch tracing

- Batch and lot tracing starting from each process stage (supplier ->customer / customer -> supplier)

Sales

Order entry

- Telephone connection (TAPI)

- Order proposal

- EDI ORDERS*

- Order history

- Open items

- Stock overview

- Empties account

- Sales information

- Conditions overview

- Online contribution margin

Picking

- Order splitting by departments (documents/workstations)

- Tour-dependent order splitting

- Weigh, scan, capture

- Mobile data acquisition (MDE)

- Product/Case/Pallet Labeling*

- NVE labeling*

- Neutral production orders

Tour planning

- Tour-dependent picking

- Tour pick lists

- Tour planning

- Display of missing order items

- Message in case of overload

- Vehicle loading lists

- Tour list for cash payers

- Tour statistics

- Tour contribution margin

- Vehicle evaluation/utilization

Delivery note/invoicing

- Delivery address/delivery point/storage location

- Delivery bill with/without price, amount

- Weight breakdown according to batches/MHD

- Combined delivery note/invoice printing

- Route-dependent delivery bill and invoice printing

- Single/weekly/collective invoice

- Invoice for central regulators

- EDI-DESADV*

- EDI-INVOICE*

Empties management

- Empties registration or automatic registration in shipping

- Automatic empties loading for forwarders

- Empties management for forwarders

- Empties account management with/without empties calculation

- Empties movement control

- Empties account statement

- Empties stock with empties value

Returns management

- Return registration

- Returns order entry

- Returns weighing module

- Return credit

- Returns evaluation according to

- Return reasons

- Representatives

- Customers/Customer Groups

- Article/article and merchandise categories

Agent management

- Representative, district manager and driver

- Commission settlement for customers/customer groups, article/merchandise groups

- by kg, piece, turnover

- Contribution margin

- Transfer of the commission settlement to financial accounting

- Evaluations according to ABC, customers/customer groups, racers, articles, article merchandise groups, region

Contract Management

- Conclusion of any number of contracts with any number of item positions

- Recognition in foreign currencies

- Contract blocking in case of overdraft

- Contract operations in different languages

- Contract reservation/booking

- Orders (order acceptance)

- Delivery bill /Invoices

Protocols

- Price change protocol

- Weighing log

- Deletion log

- Missing quantity log

- Quantity comparison (ordered/delivered)

Analyses

- Order analysis

- Customer structure analysis

- Passive customers/articles

- Pricing analysis

Evaluations

- Evaluations customer/customer groups according to article no., article/merchandise groups

- Online average price calculation

- Interface to EXCEL/ACCESS

- DSD billing

- Intrastat

Interfaces

- Scale systems of various manufacturers BIZERBA, METTLER, SYSTEC etc.

- Price labeling systems BIZERBA, ESPERA etc.

- Cash book / cash register systems

- Financial accounting/interfaces Fibunet, DATEV, KHK, LEXWARE, VARIAL, DIAMANT, SAP, SHD, BMD, NAVISION, MESONIC

- Interface archiving systems*

- EDI-ORDERS*, DESADV*, INVOICE*

- Telephone integration (TAPI)*

*optional

Production

Basic data

- Resources (machines, tools, personnel)

- Working/set-up times

- Work shifts

- Workplaces, operations, work plans

- Recipe areas and groups

- Filling quantity data

- Manufacturing instructions

- Regulations for the adjustment of machines

Production orders

- Different production order types

- Enter production orders

- Lock and release production orders

- Separation according to locations/shifts

- Production order status tracking

- Check and display material stock in production order

Demand planning

- Determination of requirements based on customer orders à Planning overview

- Inventory check taking into account purchase orders, minimum and remaining stocks

- Define explosion variants

- Material requirements explosion over n‑stages

- Material provision per department/warehouse provisional or final

Lot size planning

- Lot sizes in production planning:

- Day batches

- Partial batches

- Batch per production order

- Combine sample batches of several production orders into one lot size

- Set validity periods

Charging

- Splitting according to operations on different workstations

- Batch number management

- Note for residual quantity processing Tolerance limit check

- Automatic derecognition

- Early completion of production in the event of machine breakdowns or cancellations

- Status feedback

Scale and machine connection

- Integration of scale/conveyor systems

- Scanner, printer, BDE, MDE

- Marking and labeling systems

- Filling systems

- PLC/process controls

- Measurement data control — quality assurance (e.g. temperature/pH value)

- Machine connection/ control

Quality assurance (internal)

- Integration of quality inspection plans at all workstations

- Temperature detection etc.

- Quality information recording for relocations to cooking, smoking cabinets, etc.

Calculation

Basic data

- Resources (personnel/machinery)

- Overhead and administrative expenses

- Operations, A‑operations, routings

- Operating times, set-up times

- Cost rate units

- Cost classes

- Where-used lists for:

- Work centers in routings

- Articles used in formulations

- Text key

Dismantling calculation

- Cut lists

- Target and actual calculation

- Simulation

- Unit costing or costing run over all cutting stages

Purchase calculation

- average price update of all purchase prices with free assignment year, month, week, day etc.

- free design of overviews for comparison of purchase prices

- Purchase price calculation incl. Incidental procurement costs (unloading costs, unloading shrinkage, etc.)

- Overhead costs (purchasing department) = Cost price

Recipe calculation

- Target and actual costing

- Unit costing or costing run across all recipe levels

- Simulation

- Online calculation with free design of different calculation variants

- Save changed and current material prices

Article costing

- neutral or customer-related product calculation (kg or pieces)

- Variant selection

- Costing types

- Calculation method

- Customer-related calculation taking into account discount, bonus, cash discount, freight costs, commission

Contribution margin

- Customers, customer groups, representatives

- ABC classifications

- Articles, product groups (articles/goods groups)

- Regions, sales areas and countries

- Year/month/week comparison

Quality management

Basic data

- freely definable queries

- Create text input fields

- Create warnings

- Assignment of message texts with process instructions

- Grading and weighting parameters

Test order management

- Data acquisition at work and weighing stations in all areas of the company

- Receiving, warehouse, meat cutting, production

- Samples

- Laboratory data acquisition

- Documentation of actual and target values

- Documentation of deviations

Messages/procedures

- Triggering warning messages

- Hiding of procedural instructions

- Triggering of mails in the event of deviations to operator and/or operator groups

Complaint processing

- Automatic generation of complaint letters

- Complaint processing

- Consideration of complaints in grading

Supplier evaluation

- Quality

- Quantity

- Punctuality

- Rejection

- Complaint letter unanswered

- Predefined supplier letters

Evaluations

- Suppliers/Customers

- Internal company valuation

- Open findings data

- Supplier-related deviations

- Vendor/article evaluation

- Total supplier evaluation

- Quality criteria for the operation (procurement, production, etc.)

- Supplier evaluation

Meat cutting

Basic data

- Dismantling columns

- Cutting stages

- Packaging lines

- Article and part determinations

- Dismantling costs (personnel and machinery)

- Overheads

- Cut lists

Dismantling calculation

- Target calculation

- Actual costing and simulation

- Target/actual comparison

- Article costing taking into account fixed and variable costs

Disassembly process

- Disassembly access (weighing, scanning, recording)

- Disassembly output

- Cut piece/box and pallet label*.

- Dismantling evaluation and shrinkage determination

Disassembly evaluation

- Dismantling evaluation (inflow / outflow, in terms of quantity and value)

- Daily, weekly, monthly, annual evaluations

- Article weights per column

- Dismantling movement log

- Weighing log

- Dismantling settlement for columns

- Dismantling evaluation

*optional

Store

Store management

- Store order entry and summarization in preparation for picking

- Branch and special price lists

- The maintenance of master data for store scales and checkouts is fully automatic according to stored call-off variants

- Automatic retrieval of orders and sales movements

Scale interconnection system

- Data transmission to the store: price lists, and changed prices

- PLU numbers

- Groups of goods and articles

- Employees

- Leerguttara

- VAT codes

- Date and time

- Scrolling texts

- Bontexte

Sales call-off

- Article sales

- Article group sales

- Product group sales

- Seller Daily Sales

- Time related polling

- Cash journal

- Store sales

Sales

- Revenue recognition

- Cash accounting

- Bank deposit

- Cash target amount

- Missing vouchers

- Check sales

- Voucher sales

- Branch expenses (cash withdrawal)

- Cash transactions (bank deposits)

- Daily results

Inventories

- Edit and print inventories

- Automatic inventory valuation

- Lump-sum inventory

Evaluations

- Cash accounting

- Inventory comparison

- Daily sales

- Sales evaluations

- Store surplus calculation

- Store information system à Sales by merchandise categories, employees, times

- Consideration of goods receipts, transfer debits, returns, credit notes and inventory data in the store profit and loss statement

- Contribution margin evaluation

Livestock

Basic data

- Operating information

- Billing scheme

- Cost/rounding procedure

- Allowance and discount tables

- Quality level tables

- Findings and complaint parameters

- Freight forwarding/bonus/commission tables

- Billing layout

- Conversion tables for input and output formats

Pigs/Livestock/Sheep

- Enrollment Planning

- Tour planning

- Goods receipt/arrival

- Animal passport/ear tag detection

- Online veterinary data collection

- Online classification

- Labeling*

- HIT message

- Slaughter/classification data output

- Accounting

- Transfer to financial accounting

Livestock / livestock

- Enrollment Planning

- Tour planning

- Goods receipt/arrival

- Animal passport/ear tag detection

- HIT message

- Accounting

- Transfer to financial accounting 8

Poultry

- Enrollment Planning

- Tour planning

- Goods receipt/arrival

- Slaughter/classification data output

- Accounting

- Transfer to financial accounting

Evaluations

- Prepared statistics for suppliers, buyers and consultants

- Single animal evaluation

- Cost statistics

- Freight forwarding evaluation

- List generator for free creation of evaluations

- Data transfer to EXCEL/ACCESS

- Data output as TXT, ASCII, PDF

- Price message

Special settlements

- Bonus settlement

- Loyalty bonus statement

- Commission settlement

- Freight forwarding accounting

Extras

iFood Automotive

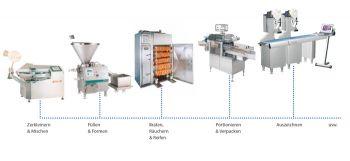

Automation is playing an increasingly important role in many areas of food production. Increasingly, machines are equipped with control and regulation programs. With iFood Automotiv, all measurement and control data can be permanently recorded and archived. Independent of the machine supplier, we create interfaces for machine communication. We network your plant technology into an information and control system for operating technology.

- Siemens S7-300 connection

- active and passive sensors

- RFiD know-how

- Document process data

Production Management

In cooperation with your operating technology, we develop and build solutions based on the latest automation technology. Targeted control and coordination can reduce your costs at virtually every level. In a system of numerous plants and machines we close the gaps. With the use of iFood, agmadata takes over, coordinates and is responsible for the implementation of automation projects and tasks.

- reliable recording and archiving

- targeted automation

- provider-independent

- Solutions for individual requirements

What we have also mastered:

- V2A stainless steel products housing and PDC, PAZ

- Mowis Mobile WWS Solution

- RFID — application possibility

- Fibu-Net — accounting system

- Simba — Accounting system

- FILERO — Electronic Archive and Info Management

- Tom Tom Work — vehicle control

- PTV Route Planning

- Mobile Field Service/Sales — Trady

- PLC communication with Siemens S7 control

- Declaration, nutritional calculation and allergen labeling of foods with ReSy4

- Interfaces to various origin data systems such as fTRACE

- BI analysis tool DeepSee

Connectors and data spaces

iFood integrates seamlessly with 360°efood. This is the first digital ecosystem in the agricultural industry in which all process participants can find each other. It is based on Fraunhofer’s International Data Spaces, a development for digital sovereignty in business ecosystems. As a member of the International Data Spaces Association, agmadata is driving the Farm & Food IDS architecture and realizing a wide variety of use cases from animal transport to fertilizer management with 360°efood.

Diverse platform offers are therefore available, the IDS Farm & Food shows solutions and concepts for a wide range of issues.

Through the networked cooperation of topic-related working groups, we arrive at more advanced solutions.

InterSystems IRIS — the database

From version 2.5.0 NG on, iFood is based on InterSystems IRIS. This powerful data platform is optimized to collect, store and process large amounts of data from multiple sources at lightning speed.

In addition, the platform offers a variety of tools and functions that help to effectively analyze and visualize the collected data.

Finally, InterSystems IRIS offers advanced capabilities such as machine learning and artificial intelligence to make better decisions and take your operations to the next level.